节省成本的紧凑型履带装载机仿真

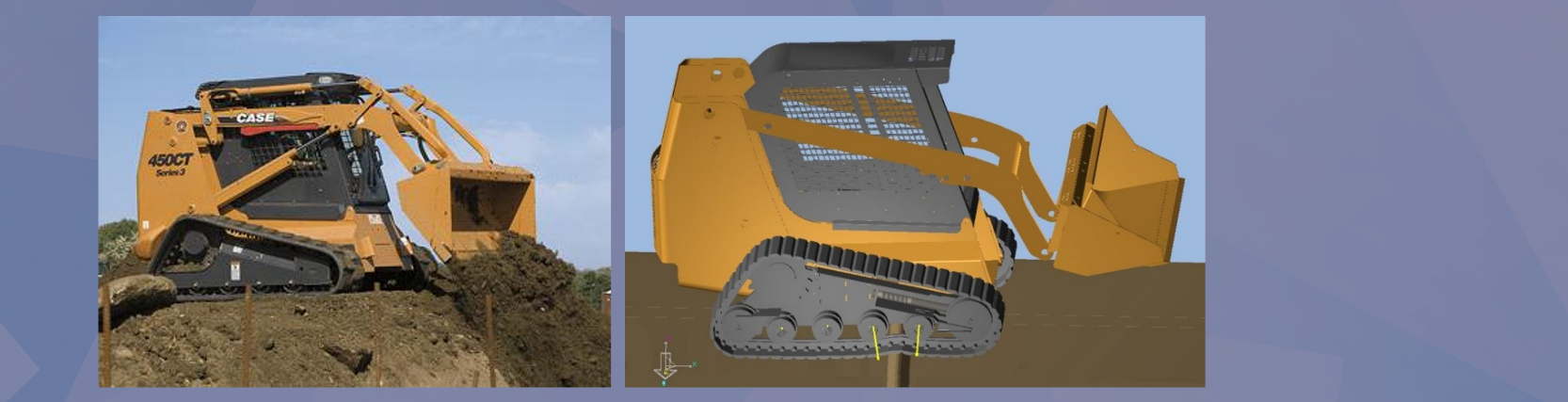

CASE NEW HOLLAND (CNH), a leading agricultural and construction equipment company, is increasing its motion simulation capabilities as its product designs evolve. One example is the design of compact track loaders that were developed to provide increased traction and reduced ground pressure as compared to traditional skid-steer loaders with tires. Since the simulation results were obtained more quickly than physical testing, CNH could focus on the areas of the design to improve the performance of the product. Through simulation, CNH could achieve system level improvements as well as component level improvements and consequently the product durability.

纽荷兰CNH(CASE NEW HOLLAND)是农机和建筑工程机械行业全球领先的知名企业,在CNH的产品设计过程中,RecurDyn动力学仿真发挥了极其重要的作用。在此,分享一个关于CNH紧凑型履带式装载机设计仿真的案例。相对于传统的轮胎式滑动转向装载机,履带式装载机能提高牵引力并降低对地面的压力。CNH通过仿真,不断地实现系统级改进和组件级改进,从而提高产品的耐久性。众所周知,仿真验证比物理试验更快,CNH充分利用仿真手段节省大量的研发时间,更专注投入在产品的设计上,推出性能更好的产品。

Customer Challenges 面临的挑战

- 研发的紧凑型履带装载机必须具有良好的耐久性能

- 需考虑履带的灵活特性

- 必须考虑履带、托辊和履带支重轮之间的接触

- 当装载机沿斜坡运行时,不能出现脱轨现象

Solutions 解决方案

- 使用RecurDyn专门的履带模板化建模工具快速地建立3D动态模型

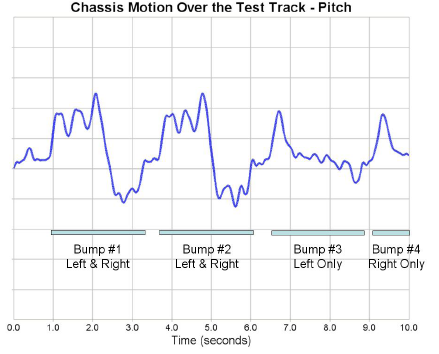

- 针对各种路况进行履带式装载机的驾驶仿真

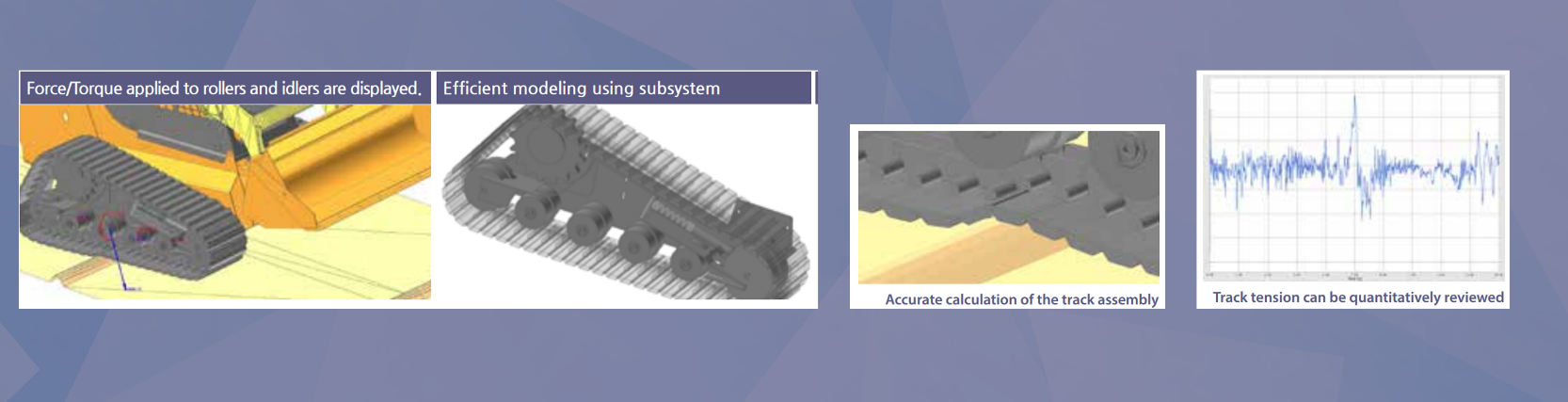

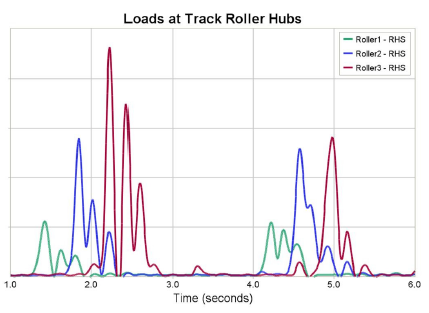

- 定量评估各工况条件下前、后惰轮和其它零件上的载荷

- 改变车轮在履带总成中的位置及车辆的质心位置进行仿真比较

- 改变履带张力进行仿真确认脱轨的可能性

- 对高应力区域附加材料的改善设计进行仿真验证

Process 流程

- 建立履带系统的动力学模型

- 通过与已有实际测试结果的比较,校正模型详细参数获得有效的仿真模型

- 通过仿真,获得物理测试无法获得或验证的输出结果

- 用最坏情况的载荷数据和部件应力进行耐久性分析

Key Technologies for Analysis 关键技术

- 采用包含各组件(滚轮、托辊等)的履带系统专用建模工具

- 自动创建履带组件间复杂的接触

- 采用子系统建模复用技术减少建模时间

- 直观可视化显示部件上的力/扭矩结果

Outcomes 效果

- 仿真大量取代物理测试,节省大量资金和时间

- 基于仿真结果的设计变更,提高了产品耐用性

- 实现了以提高产品性能为目标的仿真驱动设计

RecurDyn’s computational speed and process automation for track systems allowed us to develop accurate simulations of our compact track loaders that would have not otherwise been practical. Although we are continuing to gather data, we are confident that we are reducing our engineering costs by at least two dollars for every dollar that we invest in simulation.